Case Study: How SCS Used HP SitePrint to Streamline a 90,000 SF Warehouse Layout

- Meghan Nelson

- Aug 6, 2025

- 2 min read

When it comes to warehouse expansion, layout isn’t just a step in the process — it’s a critical milestone that impacts every trade that follows.

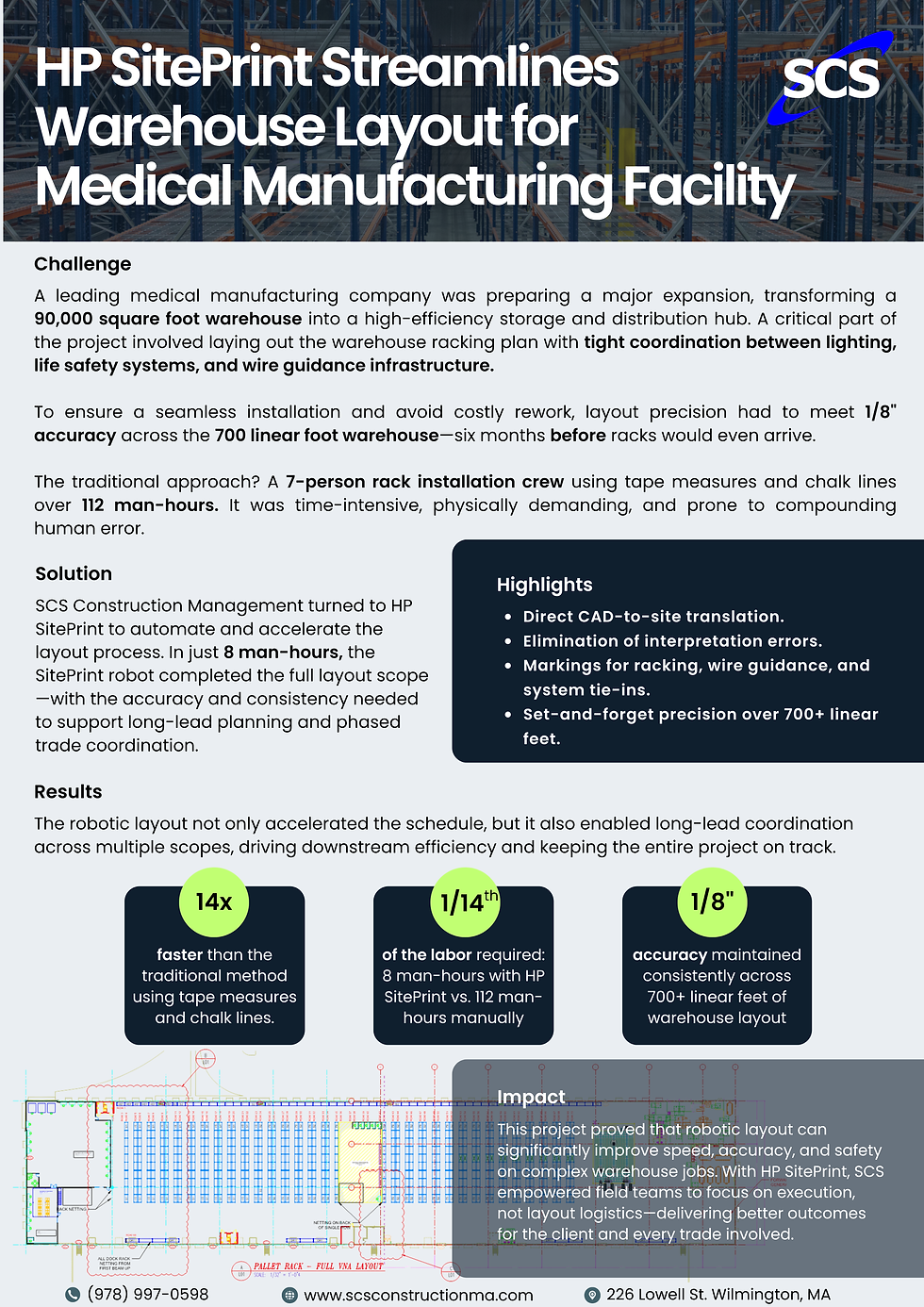

At SCS Construction Management, we recently supported a leading medical manufacturing client, ZOLL, with the layout of a 90,000 square foot warehouse. The timeline was tight. The expectations were clear. And the accuracy needed to be spot-on.

This is how we used HP SitePrint to deliver consistent results, reduce labor demands, and keep the project on schedule.

The Challenge: High Accuracy, Long Lead Time, and Zero Room for Rework

The client was preparing for a major expansion and needed the racking layout completed six months before equipment installation. On top of the long lead time, the project required 1/8-inch accuracy across more than 700 linear feet to coordinate with lighting, life safety systems, and wire guidance infrastructure.

Traditionally, a layout of this scale would take a 7-person crew over 112 man-hours, using tape measures and chalk lines. That method works — but on a complex project like this, it introduces risk:

Interpretation errors between crews

Compounded layout drift

Significant time and labor cost

Potential delays for downstream trades

The client needed a faster, more reliable way to get the layout completed early, without sacrificing precision.

The Solution: Bringing HP SitePrint to the Field

To meet the timeline and accuracy requirements, we turned to HP SitePrint, a robotic layout system that prints directly from CAD files onto the warehouse floor.

Within just 8 man-hours, HP SitePrint completed the full racking layout — a 93% reduction in labor compared to traditional methods.

The robotic system produced consistent, high-accuracy markings for:

Racking alignment

Wire guidance systems

Life safety tie-ins

By removing the guesswork and manual measuring, we ensured that the layout was executed cleanly and accurately — setting the stage for downstream scopes to begin without delay.

The Results: Better Accuracy, Less Labor, and a Smoother Project

Here’s what we delivered:

14x reduction in layout time (8 MH vs. 112 MH)

1/8-inch accuracy maintained across the full layout

Early coordination enabled for long-lead scopes

Schedule alignment with all trades on site

Minimized rework risk through precise execution

By completing layout earlier in the project lifecycle, we gave every trade — from lighting to fire protection — a clear path forward. No delays. No backtracking. No wasted hours.

Why It Matters

Efficient layout isn’t about moving fast — it’s about moving right.

At SCS Construction Management, we invest in tools like HP SitePrint because we’ve seen how they impact the entire job. From reduced labor to fewer field conflicts, the benefits compound over time — especially on large, phased, or heavily coordinated projects.

For owners, developers, and project teams looking to stay ahead of schedule and reduce cost risk, robotic layout is no longer a luxury — it’s a strategic advantage.

Interested in Exploring Robotic Layout?

We’re happy to walk through how this approach could apply to your next facility upgrade, warehouse build-out, or renovation. Whether it’s early layout planning or full construction management, our team is here to help you build smarter.

Comments